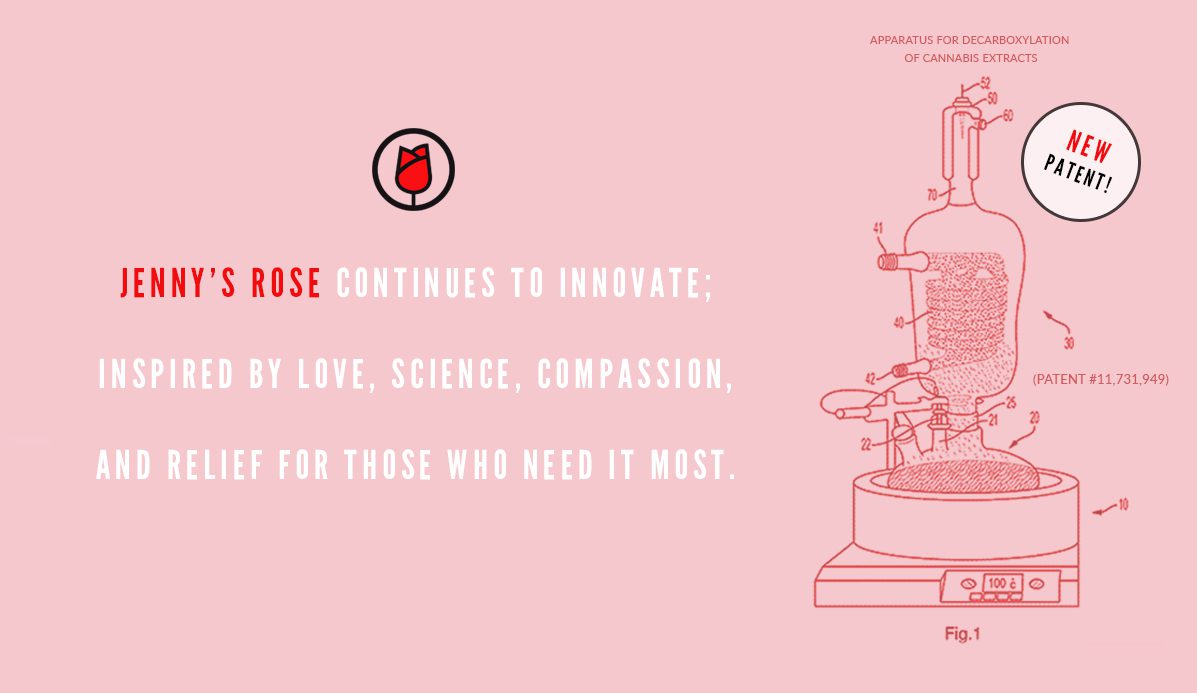

In the ever-evolving world of cannabis innovation, Jenny’s Rose continues to break new ground with a unique patented extraction apparatus that unlocks the full potential of this remarkable plant. As we celebrate our fifth patent, Jenny’s Rose is set to redefine the way we extract and utilize the many benefits of cannabis. Imagine a method that allows you to activate all the therapeutic cannabinoids without sacrificing essential components like terpenoids and fats. This revolutionary technology does just that, preserving the complete spectrum of cannabis goodness. Let’s dive into the science behind this invention and discover how it’s transforming the world of cannabis extractions.

Meet Jimmy Castillo: The Visionary Behind the Invention

Meet Jimmy Castillo: The Visionary Behind the Invention

At the heart of this extraordinary breakthrough is Jimmy Castillo, the Chief Science Officer and Founder of Jenny’s Rose. Jimmy’s unwavering dedication to helping and guiding others through their journey to relief from chronic issues has become his life’s work and obsession. All of his hard work and research has culminated in the development of a novel extraction tool for maximizing the full plant benefits of cannabis. His invention represents a paradigm shift in the industry, ensuring that none of the essential cannabis components are lost during the extraction process. Imagine it as a super low-temperature cooker that carefully retains all the nutritional benefits and flavors, creating the perfect cannabis product.

The Challenge: Decarboxylation of Cannabinoids

The key challenge in cannabis extraction is the decarboxylation of cannabinoids, a process critical for unlocking their therapeutic potential. Traditional methods involve subjecting cannabis plant extracts to high temperatures, usually above 100°C, for extended periods. While this decarboxylates the cannabinoids, it also leads to the breakdown of these valuable compounds and the loss of volatile components like terpenoids.

Decarboxylation is a time and temperature-dependent process, and manufacturers must strike a delicate balance to optimize their yields. But the goal is clear: to convert non-decarboxylated cannabinoids into biologically active molecules without generating unwanted byproducts. For example, heating THC-A at 100°C for 3 hours can convert it to THC, but at the same time, it may increase the conversion of THC to CBN, an undesired compound. This loss and degradation of cannabinoids is a significant concern for manufacturers aiming to create a specific cannabinoid profile in their final product.

The Innovative Solution: Controlled Decarboxylation

Enter the patented invention—an ingenious solution that tackles the decarboxylation challenge head-on. This revolutionary apparatus and method for controlled decarboxylation of cannabinoids ensures that the delicate balance is maintained throughout the process. Here’s how it works:

1. Reflux Apparatus: The heart of the invention is a novel reflux apparatus designed to maintain precise control over temperature and prevent the breakdown of cannabinoids and volatile components like terpenoids, flavonoids, and desirable plant lipids and waxes.

2. The Mixture: In the lower chamber of the apparatus, a mixture is carefully prepared, containing cannabis plant extract with non-decarboxylated (acidic) forms of cannabinoids, terpenoids, and other valuable plant materials.

3. Heat and Cool: The lower chamber sits atop a heat source and is connected to an upper chamber via a short-neck. The temperature is monitored closely, maintained between 80°C and 120°C. The upper chamber features a cooling core that circulates coolant to maintain a lower temperature, condensing vapor in the upper chamber. This condensed liquid then returns to the lower chamber.

4. Cooling Core: This cooling core is the secret sauce of the invention. It’s chilled to a temperature well below freezing, typically between -30°C and -40°C. While cooling vapor streams is common in cannabis extraction, what sets this invention apart is the use of such low temperatures to ensure superior retention of volatiles and the prevention of cannabinoid decomposition.

5. Controlled Decarboxylation: The mixture is subjected to controlled decarboxylation by gently heating it in the lower chamber. As the temperature rises, volatile components vaporize, only to condense back into the mixture in the upper chamber. This ensures that none of the essential compounds are lost, resulting in a high yield of decarboxylated cannabinoids.

Incredible Results: A New Era for Cannabis Extractions

The results speak for themselves. This patent allows manufacturers to achieve effective decarboxylation of cannabinoids while preserving the integrity of volatile components. It’s a delicate balance that ensures the production of high concentrations of decarboxylated cannabinoids, all without generating unwanted byproducts like CBN. The apparatus and method enable precise control over the composition of the final product, empowering manufacturers to tailor their extractions to meet specific goals.

Conclusion

Jimmy Castillo’s patented invention is nothing short of revolutionary. It has ushered in a new era for cannabis extractions, where the full potential of this remarkable plant can be harnessed without compromise. With this technology, the cannabis extration process has taken a giant leap forward, ensuring that every drop of extract is packed with all the benefits the cannabis plant has to offer. This invention is a testament to human ingenuity, unlocking the secrets of a plant that has fascinated and intrigued us for generations. As we look ahead to a future filled with endless possibilities for cannabis-based therapies, one thing is certain: Jenny’s Rose will be at the forefront of innovation, science, and compassionate care, guiding the way toward relief for those who need it most.